-

Posts

39 -

Joined

-

Last visited

-

Days Won

3

ttarkan last won the day on March 7 2023

ttarkan had the most liked content!

About ttarkan

Personal Information

-

First Name

Tolgahan

-

Last Name

Tarkan

-

Company/University Name

Simulation Helpdesk OÜ

Converted

-

OCCUPATION

CEO at www.simulationhelpdesk.com

- WEBSITE

Recent Profile Visitors

3,312 profile views

ttarkan's Achievements

-

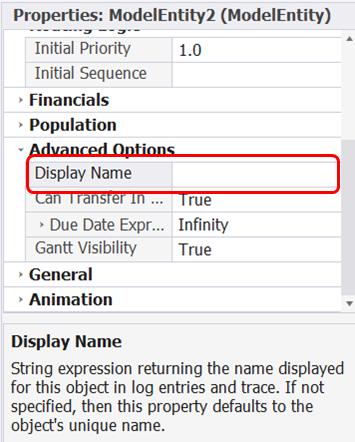

You can set the display name property of the modelentity under advanced options to the state variable you have defined so it will show that variable of the entity in the Gannt chart and trace.

-

I have large AGV network where AGVs pass through several junctions to reach their destination, and they may wait a while at junction till their path is cleared (traffic lights logic). There are three types of junctions always repeating, I also want to collect statistics based on junctions. So I have created a submodel for junctions with their own path network & logic and added them to my model. I have tested the system with entities going randomly with destination is set to "continue" and it works well waiting at junction based on traffic light logic. However when I use a specific destination node for the entity inside the main model, the entity goes to target in Freespace, my main model doesn't recognize the paths inside the submodel. So I have created a new network element and connected it to a data table for its member links. I have added all the submodel and model links in the data table. Eventhough the network now has all the connections in the model and submodels. It still cannot calculate the path distance so it will go to destionation using freespace. Is there any way to remedy this? Do I have to remove all my submodels?

-

Hi Gabriela, Here are two ways you can do that: 1) You may add transfer-out constraints to workstation object, so the entity cannot transfer-out from the object even if its task sequence is complete. 2) In the end of task sequence you may add a task with type "Process" and choose the process you want to run in this step. Then inside the process use a scan step to check for the condition you want to be true before you transfer the entity even out of the "processing contents" of the workstation. Hope this helps.

-

How to model a carousel that rotates into a server?

ttarkan replied to WD0001's topic in SI General Discussions

I would suggest the following solutions Solution 1 1) You can use vehicle or worker object to "pickup" entities to 1A Node. 2) Change the worker picture to make it look like a "server" object. 3) You can keep the existing Server1 and Server2 objects. 4) For modeling processing time and any process related stuff you can make a copy of the entity when it is loaded to the "ridestation" of worker and transfer the new entity to the server object. Solution 2 (recommended) 1) When Entity enters 1A create a transfer out constraint to stop entity moving forward. Such as a variable on modelentity =0 2) Create a Server with processing time = Task sequence 3) Enter any process related data and rule into task sequence 4) Move your worker (coursel) along the path using the task sequence. 5) When you want to transfer the entity to another object or make it continue moving along the conveyor, set the modelentity variable related to constraint condition to true. Hope this helps, Best regards -

Entities not Unloading the Transporter (urgent)

ttarkan replied to mateus's topic in SI General Discussions

Hi Mateus, I see you assigned a route to the bus vehicle but as I see you haven't assigned the destination to entities. In order to assign the destination to entity you can use the "set node" step in process tab. I haven't used a sequence based vehicle before so I am not sure if it will solve the problem alone. But if it doesn't solve you may use transfer step to transfer entities from vehicle.Ridestation to your desired destination when the bus arrives there. Also pay attention to transfer one entity at a time and then repeat the loop or else you can batch a bunch of entities first then transfer them. Also you might need end transfer step to end the entity being at transferring stage if you have defined a custom station that you are transfer the entities to. -

Use for loop to traverse members of a list

ttarkan replied to GHao's topic in SI General Discussions

You can create a new object reference state variable in vector format then assign object reference to the any row of this array using assign step. When choose your vector type variable Simio will let you enter the row number as well in the assign step as seen in figure below. When you want to refer to second row of a vector type state variable use the following syntax: ObjectReferenceState1[2] When you want to refer to second row and third coloumn of a matrix based variable use the following syntax: ObjectReferenceState1[2,3] That is inside the squared brackets, first value indicates row and second value indicates coloumn index of the variable. Then you can use loop to increment a token based variable and decide step to search a vector type variable. But I suggest creating a table for these objects and using search step as well. -

So lets say task B is dependent on Task A, hence Task A has sequence value 10 and Task B has sequence value 20 (Task A preceeds TaskB). Task A branch type should be conditional and for the condition formula should be written in to the "condition or probability" fieldç For Task B enter the processing time and other data as usual. If the auto-cancel trigger is set to "All immediate predecessors cancelled" (as it is by default), Task B will be cancelled if the condition for Task A didnt return true value. Hope this helps

- 1 reply

-

- 1

-

-

Is it possible to use neural networks with continious flow library? I have a microgrid simulation model with solar panels which charges a battery and grid are energy sources for a house. Grid charges at different rates based on time of use (TOU, i.e time of day and winter summer holiday etc) and solar company charges at fixed rate as energy is filled into battery. I would like to optimize the system using machine learning so that the house minimizes their bill by deciding when to chose grid and solar.

-

You can also use produce consume material method to add requirements to a process or processing step. You can see it when you change the process type to Task Sequence from Specific time. You can add more than one material requirement by adding tasks in parallel with same sequence number and specificying the material name and quantitiy that will be consumed for each parallel task. In that way you dont need to create and destroy uncessary entitites.

-

ttarkan started following Rate tables not working

-

Just want to remind you that the values in the rate table shows the offset from the simulation start time. Not actual day time. So if your simulation start time is 7 am your first row shows 7 am to 8am time frame and so on. Hope this helps Regards

-

Try adding the value zero for the last three lines of the rate table. Set the interval size to 1hr. That should fix your problem.

-

Hi All, I want to do some calculations just before the simulation ends. I did it previous versions without problem but now on version 15.247, "on run ending" add-on process is not being executed.I tested it even on a new simple model file with source server sink. There is just two assign steps with breakpoints on the add-on process. But in model trace it doesnt show the add-process name, the state variable value is not assigned, and breakpoint is not reached. Anyone experiencing the same problem in this version? Is there a quick solution to this? Or do I have to install older version? Kind regards, Tolgahan

-

ttarkan started following Simio-Related Positions Desired or Positions Available

-

I found the answer again. For those who want to know: step 1) Add replenishment policy property to data table step 2) Chose a default value for replenishment policy step 3) Click default values of dynamic properties According to selection made in step2, the list of properties now appear at step 3. (If min/max is selected OrderUptoLevel and Reorder Point will appear)

- 1 reply

-

- materials

- data tables

- (and 6 more)